ROBOTIC FABRICATION AND DRAWINGS

2016 - PRESENT

The ACADIA Workshop focused on the exploration of the design potential of encoded feedback responses to dimensional errors during the production process as well as investigating the constraints and opportunities that come with non-layer-based 3D printing processes and deploying minimal material for maximal geometric definition. In this workshop, I experimented with the use of spatial extrusion, collaborative robotics, real-time scanning, and adaptive part variation to explore the generation of adaptive frame structures extruded in midair.

Away from workshop, I designed and 3D print with robot an idea in University of Michigan to explore how by printing 2D flexible materials we can make 3D reconfigurable spaces. This can provide us a great opportunity to have offsite fabrication, efficient transportation and easy installation and assembly of 2D components to make 3D spaces. This is a test of how joints and connections could be embedded in design for more efficient assembly. It also provides different design outputs from the same structure. Such approach gives users an opportunity to shape their built environment based on their own preferences.

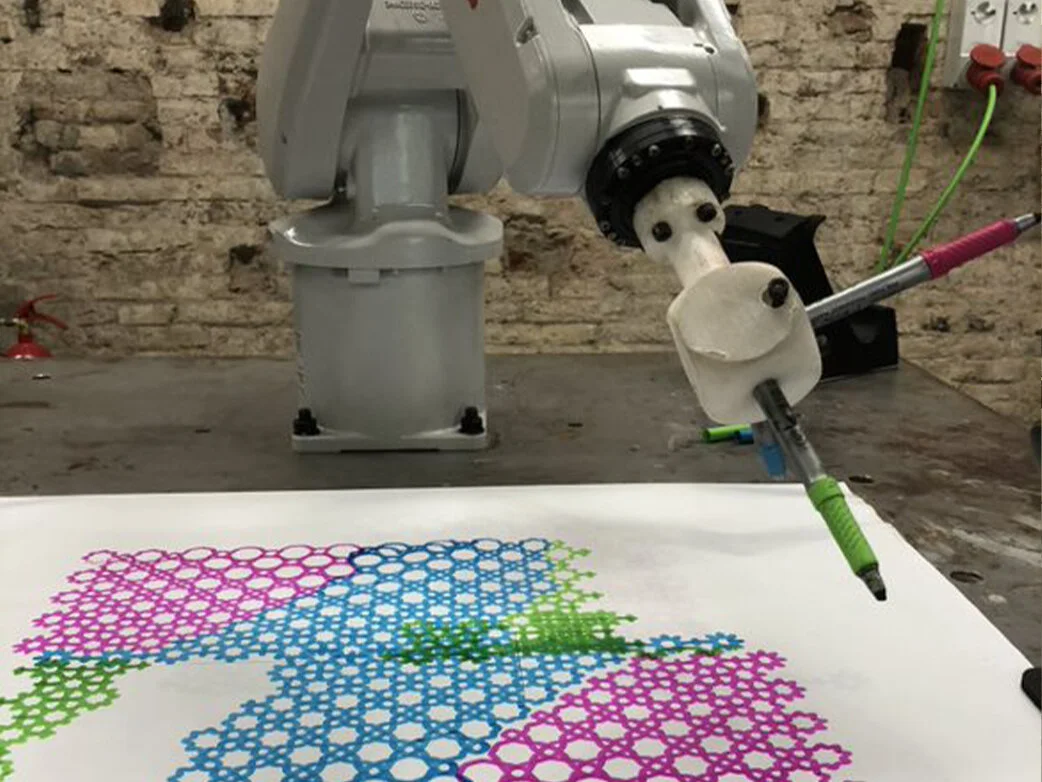

During my residency in IAAC, I developed my expertise in robotic 3D printing, this time with exploring robotic clay 3D printing and drawing with robots.